石材表面加工英文术语

Polished: To smooth or brighten a surface increasing the reflective quality and luster by chemical or physical processes. Generally gloss levels should be + 90 as measured by a gloss meter. To achieve this, final polishing should have been done by latest Italian/ French machines using imported abrasives.

Buffing: Using a non-abrasive pad attached to a machine, which rotates the pad in a circular fashion over the stone, generally between 150-300 RPM. Polishing formulations containing micro-fine abrasive materials are used with buffing to produce a more reflective gloss on the surface of stone. Waxes are also used with buffing to enhance the gloss of polished stone.

Honed: To grind a surface with a high grit material to a uniform specification without producing a reflective surface.

Sawn: i.e. unpolished. It is not advisable to buy this way because : floor polishers do not give as good a polish as factory machine polishers. many defects are not visible easily before polishing.

Calibration: To grind a surface with a high grit material to a uniform surface to maintain the thickness variation.

Gangsaw: To grind two sides of the stone surfaces with a high grit material to a uniform specification without producing a reflective surface.

Shade variation: Slabs / tiles should be sorted to ensure uniformity of shade. Normally, any colour can be sorted into three shades. Sorting is simple -just lay all the material on the floor and look from different directions.

Colour patches: These are darker or lighter patches or bands of single colours due to mineral localisation.

Scratches: The marring of the surface caused by physical trauma such as small stones or sand embedded in shoes scraping across a marble floor.

Staining: The absorption of foreign pigments or oils into the porous stone causing discoloration.

Double color: Sometimes two different grain sizes occur in the same slab, giving the appearance of a double colour.

Free lengths: i.e. lengths varying randomly while width is constant are also very attractive. Choose the widths as per the expected floor area. Buy random lengths and cut at your site to fit.

Flatness Tolerances

A 4’ dimension in any direction on the surface shall determine variation from true plane, or flat surfaces. Such variations on polish, hone, and fine rubbed surfaces shall not exceed tolerances listed below or 1/3 of the specified joint width, whichever is greater. On surfaces having other finishes, the maximum variation from true plane shall not exceed the tolerance listed below or + 3 mm of the specified joint width, whichever is greater.

Polished, honed or fine rubbed finishes... + 0.5 mm

Sawn, Calibrated, 4-cut and 6-cut.... + 1 mm

Edges also can be chamfered / bevelled. Chamfering removes whiteness and chipped edges. This looks very good. Chamfering is a simple process in which a polishing brick is run at an angle of 45 ?

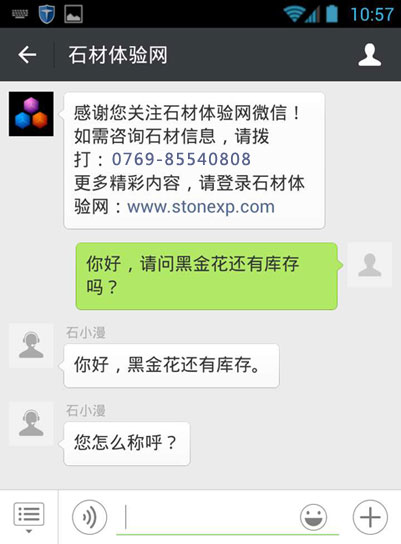

• 凡注明“石材体验网”的所有文字、图片、音视频、美术设计和程序等作品,版权均属石材体验网所有。未经本网授权,不得进行一切形式的下载、转载或建立镜像。

• 您若对该稿件内容有任何疑问或质疑,请即与体验网联系,本网将迅速给您回应并做处理。

点击右侧【在线咨询】或至电0769-85540808 处理时间:9:00—17:00

石材体验网部份作品均是用户自行上传分享并拥有版权或使用权,仅供网友学习交流,未经上传用户书面授权,请勿作他用。